Description

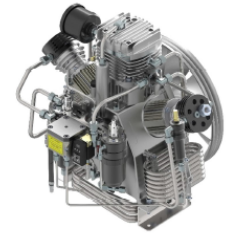

DIVING COMPRESSOR PACIFIC E (Eco) SERIES by NARDI Compressor

BREATHING AIR is a product line that includes several products made by NARDI COMPRESSORI which are designed to provide breathable air for the filling of cylinders for different applications (i.e.: scuba diving, safe & rescue, military, etc.). PACIFIC is a range of compressors of different flow rates that have a very high efficiency and are very robust to ensure many hours of continuous operation.

BREATHING AIR is a range of High-Pressure Compressors that includes several models designed & manufactured by NARDI COMPRESSORI to provide breathing air for the filling of scuba diving cylinders. ATLANTIC is a highly efficient and mechanically strong compressor and at the same time, it is compact and easy to carry around.

QUALITY OF COMPRESSOR BLOCK

The compressor block, or pump unit, is the heart of the ATLANTIC compressor. This is a critical component on which NARDI has put an important technical effort. Its features include the use of light alloys with high thermal efficiency, the aluminum alloys also used for the compressor block, and all components are made of anticorrosion and quick heat dissipation materials.

The crankshaft bearings are all made in Europe and their high quality guarantees the compressor a longer lifetime. Cooling of the compressed air is done through the interstage aluminum and stainless steel cooling coils system. This is a small-sized compressor with 4 compression stages with all piston rings made in cast iron providing high performance over time.

EFFICIENCY OF THE FRAME

The frame is designed to reduce weight and dimensions, making the compressor light and portable, with an aluminum frame coated with epoxy powder paint. The powder coating and stainless steel components protect the compressor against corrosion in marine environments.

PURITY OF FILTRATION

The compressor is equipped with a filter and a separator that guarantees the quality of breathing air in conformity with the UNI EN 12021:2014 standards.

ECONOMY

Everything in the compressor is designed to optimize both the operating and labor costs. When the compressor is working, thanks to its NARDI-designed automatic condensate drain, equipped with a

unique patented SLOW FLOW SYSTEM, there is a reduction of the quantity of gas expelled with an 80% saving on pressurization of the entire system.

FILLING VALVES

The compressor comes with high-pressure filling valves with several different connectors both for 200 Bar and for 300 Bar. These components are very easy to use. In fact, with a simple turn of the knob, you can close the air passage and depressurize the valve to be able to disconnect the cylinder. All technical data may be changed

The bearings of the crankshaft have rollers, extremely robust and made in Europe which guarantee a long life of the compressor. An oil pump provides a constant lubrication of the inner workings of the block with oil cleaned of impurities by a filter and by a magnet which catches any metals present in the lubricating oil. The compressed air cooling is obtained by interstage stainless steel cooling coils.

MADE IN ITALY BY NARDI COMPRESSOR

Reviews

There are no reviews yet.